Introduction to Steam Boiler Piping Diagrams

Steam boiler piping diagram are essential tool that provide a visual representation of the piping system associated with a steam boiler. They illustrate the layout, connections, and components involved in the distribution of steam, condensate, and water throughout the system. Understanding these diagrams is crucial for anyone involved in the design, installation, operation, and maintenance of steam boiler systems.

Importance of Understanding Steam Boiler Piping

A comprehensive understanding of steam boiler piping is vital for several reasons. Firstly, it ensures the efficient and safe operation of the boiler system. Properly designed and installed piping minimizes pressure drops, optimizes heat transfer, and reduces energy waste. Additionally, understanding the piping system enables effective troubleshooting, maintenance, and repair of any issues that may arise.

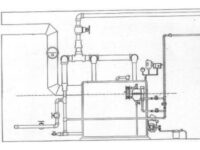

Components of a Steam Boiler Piping System

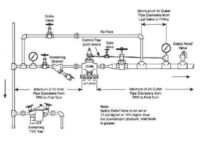

A steam boiler piping system consists of various components, each serving a specific purpose. These components include the main steam line, condensate return line, steam supply piping, boiler feed water line, blowdown line, safety valve discharge line, feedwater return line, chemical injection line, steam traps, steam distribution header, radiator or heat exchanger connections, condensate collection and drainage system, pressure and temperature gauges, vent and exhaust lines, expansion joints, and insulation and pipe support.

Boiler Room Layout and Piping Design Considerations

The layout of the boiler room and the design of the piping system play a crucial role in the overall efficiency and functionality of the steam boiler system. Factors such as space availability, accessibility, and safety regulations need to be considered during the design process. Proper planning and adherence to codes and standards ensure optimal performance, ease of operation, and maintenance convenience.

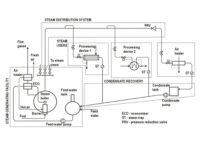

Main Steam Line: Connecting the Boiler to the Distribution Network

The main steam line is the primary artery that connects the steam boiler to the distribution network. It carries high-pressure steam from the boiler to various applications, such as heating systems, industrial processes, or power generation. The main steam line requires proper insulation to minimize heat loss and ensure efficient steam delivery.

Condensate Return Line: Efficiently Returning Condensate to the Boiler

The condensate return line is responsible for collecting and returning condensate, which is the liquid formed when steam loses its heat energy. Efficient condensate return is crucial as it allows the recovery of heat energy and reduces the need for additional boiler feed water. Proper insulation and the use of steam traps aid in the efficient operation of the condensate return line.

Steam Supply Piping: Delivering Steam to Various Applications

The steam supply piping branches out from the main steam line and delivers steam to the intended applications. The design and sizing of the steam supply piping depend on factors such as the required steam flow rate, pressure drop limitations, and the distance to the applications. Careful consideration should be given to pressure drop calculations to ensure adequate steam delivery and prevent potential performance issues.

Boiler Feed Water Line: Supplying Water to the Boiler

The boiler feed water line supplies water to the boiler for steam generation. The water source should be clean and treated to prevent scale formation, corrosion, and other water-related issues. Proper design and installation of the feed water line ensure adequate water supply to the boiler while maintaining proper pressure and flow rate.

Blowdown Line: Removing Impurities from the Boiler

The blowdown line allows for the removal of impurities, sediment, and dissolved solids from the boiler. Regular blowdown is necessary to maintain water quality and prevent the accumulation of harmful substances that can affect boiler performance and longevity.

Safety Valve Discharge Line: Ensuring Pressure Relief

The safety valve discharge line provides a path for the release of excess pressure in the boiler. It is crucial for the safety of the system, as it prevents the boiler from overpressurizing and potential catastrophic failures. The discharge line should be properly sized and directed to a safe location to prevent harm to personnel and equipment.

Feedwater Return Line: Returning Water to the Boiler

The feedwater return line collects and returns water from various processes back to the boiler. It ensures the continuous supply of water for steam generation. The return line should be properly designed to prevent pressure losses and maintain adequate water flow.

Chemical Injection Line: Introducing Chemicals for Water Treatment

Water treatment is essential to prevent scale formation, corrosion, and microbial growth within the boiler system. The chemical injection line facilitates the introduction of water treatment chemicals into the boiler feed water. Proper dosing and monitoring of chemicals help maintain water quality and protect the boiler from damage.

Steam Traps: Controlling Condensate Removal

Steam traps play a vital role in removing condensate from the steam distribution system. They allow the condensate to drain while preventing the loss of steam. Proper selection and installation of steam traps ensure efficient condensate removal, prevent steam loss, and maintain optimal system performance.

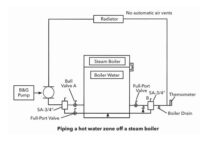

Steam Distribution Header: Branching Steam to Different Lines

The steam distribution header is a manifold that branches the main steam line into multiple smaller lines for various applications. It distributes steam evenly to different processes, heating systems, or equipment. Proper design and sizing of the distribution header ensure balanced steam flow and prevent pressure imbalances among different branches.

Radiator or Heat Exchanger Connections: Transferring Heat to Spaces or Processes

The radiator or heat exchanger connections enable the transfer of heat from steam to spaces or processes that require heating. Proper sizing and installation of these connections ensure efficient heat transfer and maintain desired temperatures in the target areas.

Condensate Collection and Drainage System: Handling Condensate in the Piping

The condensate collection and drainage system consists of pipes, traps, and other components that collect and remove condensate from various points in the system. It ensures the proper disposal of condensate and prevents its accumulation, which can negatively impact system performance and cause damage.

Pressure and Temperature Gauges: Monitoring Boiler Performance

Pressure and temperature gauges are essential instruments for monitoring the performance of the steam boiler system. They provide real-time readings of pressure and temperature, enabling operators to maintain safe operating conditions and identify any anomalies or deviations.

Vent and Exhaust Lines: Releasing Air and Combustion Byproducts

Vent and exhaust lines serve the purpose of releasing air and combustion byproducts from the boiler system. Proper venting ensures proper combustion and prevents the buildup of harmful gases, such as carbon monoxide. Venting systems should be designed and installed according to local codes and standards to ensure safety.

Expansion Joints and Flexibility: Allowing for Thermal Expansion

Steam boiler piping systems experience thermal expansion and contraction due to the temperature changes. Expansion joints and flexible connections accommodate these movements, preventing stress on the piping and potential damage. Proper placement and installation of expansion joints ensure the integrity of the system and prevent leaks or failures.

Insulation and Pipe Support: Maintaining Energy Efficiency and System Integrity

Insulation plays a crucial role in maintaining energy efficiency by minimizing heat loss from the steam piping system. Proper insulation of pipes and equipment reduces energy consumption and ensures the delivery of hot steam to the intended applications. Pipe supports are essential for maintaining the integrity of the system, preventing sagging or excessive strain on the piping.

Valve Types and Functions in Steam Boiler Piping

Various types of valves are used in steam boiler piping to control the flow, pressure, and direction of steam, condensate, and water. These include gate valves, globe valves, ball valves, check valves, and control valves. Each valve type has specific functions and applications within the piping system.

Control System Integration: Connecting Piping to Boiler Controls

The steam boiler control system integrates with the piping system to ensure proper operation and control of the boiler. It includes control valves, sensors, actuators, and other components that regulate steam flow, pressure, and temperature. Proper integration between the control system and piping ensures accurate control and optimization of boiler performance.

Safety Considerations in Steam Boiler Piping Design

Safety is of paramount importance in steam boiler piping design. The design should adhere to safety codes and regulations to protect personnel and equipment. Considerations include proper venting, pressure relief devices, safety valves, and emergency shutdown procedures. It is essential to implement safety measures to prevent accidents, overpressurization, and other hazards.

Common Issues and Troubleshooting in Steam Boiler Piping

Steam boiler piping systems may encounter various issues over time. Common problems include leaks, pressure drops, water hammer, improper steam distribution, and blockages. Troubleshooting these issues involves identifying the root cause, inspecting the affected components, and taking appropriate corrective actions to restore proper system functionality.

Maintenance and Upkeep of Steam Boiler Piping System

Regular maintenance is crucial to ensure the longevity and efficiency of the steam boiler piping system. Maintenance tasks include inspecting for leaks, cleaning pipes and traps, checking insulation, verifying valve functionality, and monitoring system performance. Proper upkeep helps prevent system failures, improves energy efficiency, and extends the lifespan of the equipment.

Conclusion

Understanding steam boiler piping diagrams is essential for anyone involved in the design, installation, operation, and maintenance of steam boiler systems. Each component and connection plays a critical role in the efficient and safe distribution of steam, condensate, and water. Proper design, installation, and adherence to safety codes are essential for optimal system performance. Regular maintenance and troubleshooting are necessary to address any issues and ensure the longevity and efficiency of the steam boiler piping system.